Slotting

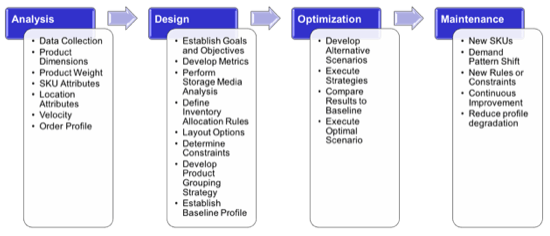

Slotting is the process of organizing how items are physically positioned within the warehouse for order picking purposes. Slotting Optimization is designed to optimize and maintain pick-lines by calculating the ideal pick location for each item in the warehouse. It helps clients determine the best placement of items in the warehouse based on item and location attributes, picking history, and picking forecast information. This enables warehouse managers to optimize the placement of merchandise by tracking each item’s pick location and identifying any slotting change recommendations.

Are You a Slotting Candidate?

- Are burdensome replenishment volumes adversely effecting your ability to complete pick waves on time, pick accurately or productively?

- Is travel time accounting for more than half of your pick/replenishment labor time?

- Are your pick rates not in line with industry best practices?

- Does your pick and replenishment productivity levels decrease when you enter a new season?

- Are you planning on implementing a WMS solution in the near future?

If the answer is yes to any of these questions, you may be a candidate for a slotting optimization project ….

Operational costs, customer service levels, inventory performance and carrying costs are all impacted by slotting. When replenishments become too frequent, handling costs increase, picking is less productive, product damages increase, service levels suffer and turns are reduced. A well-designed inventory slotting plan will optimize space utilization and minimize the time and effort required to efficiently receive and store incoming products, increasing productivity and greater facility throughput.

Inventory slotting, or profiling, is a highly effective tool used to determine the most efficient placement of products in a distribution center or warehouse. An optimal profile improves the speed and accuracy of picking, resulting in increased efficiencies and reduced labor costs. Because each warehouse or distribution center is unique, proper slotting is dependent on your distinct product, movement and storage characteristics.

Several factors also affect your slotting strategy, such as product seasonality, usage, marketing and advertising promotions, and sales projections, which requires businesses to make adjustments as product demand changes. Product placement must be regularly reviewed and maintained. The amount of change in SKUs and their movement is the primary factor in determining the optimal frequency for updating your slotting strategy.

ETHOS AND HONOUR’s slotting experts have assisted clients in developing slotting tools designed to deliver improvements in such areas as:

- Work balancing

- Pick-path optimization

- Accuracy

- Ergonomics

- Product pre-consolidation

- Efficient replenishment

- Picking productivity

- Load balancing

ETHOS AND HONOUR offers Slotting analysis as a value-add service to both ETHOS AND HONOUR’s Facility Layout & Design and Distribution Operations Assessment.